PM312 Track Undercarriage Cold Planer

The Cat PM312 is an efficient, 高度可操作的铣床,切割宽度为1225毫米(48.2英寸),执行控制的全深度清除沥青和混凝土路面 ...

Cutting System

- Milling Width

- 48.2in

- Maximum Milling Depth

- 13in

- Rotor Speeds

- 97 / 109 / 121 rpm

- Number of Bits

- 106

Power Train

- Rated Power

- 343HP

- Engine

- C9.3B

- Maximum Travel Speed

- 3.4mile/h

- Maximum Milling Speed

- 108ft/min

Weights

- Operating Weight

- 47407lb

- Transport Weight

- 46506lb

Dimensions

- Operating Length - Conveyor Up

- 36.45ft

- Operating Width

- 8.33ft

- Height - Canopy

- 12.3ft

- Maximum Truck Clearance

- 15.42ft

- Minimum Right Cutting Radius

- 6.3ft

- Minimum Left Cutting Radius

- 13.58ft

- Conveyor Swing

- 60 degrees from center

- Transport Length

- 30.58ft

- Transport Width

- 8.33lb/in

- Transport Height

- 9.84ft

Service Refill Capacities

- Diesel Exhaust Fluid (DEF) Tank

- 12.4gal (US)

- Water Spray System Tank

- 332.9gal (US)

- Fuel Tank

- 137.9gal (US)

- Hydraulic Tank

- 14.5gal (US)

- Engine Oil

- 7.9gal (US)

- Cooling System

- 16.9gal (US)

Efficient Performance

- Cat® C9.3B engine meets U.S. EPA Tier 4 Final, EU Stage V, and Korea Stage V emission standards and offers increased power density with improved electronic, fuel, and air systems

- 发动机怠速管理和多转子转速优化输出和对发动机的需求

- 变速冷却风扇以尽可能低的速度运行,以达到最佳冷却效果

- Automatic load sensing on the rotor adjusts milling speed to prevent stalls and optimize production

Maneuverability and Control

- 坚固的推进系统在每条腿上都有双位移马达, 利用交叉驱动模式,在直线切割额外的牵引力

- Automatic traction control helps reduce track slip consistent speed in the most challenging applications

- Articulating right rear leg maximizes stability and traction in demanding cuts while enhancing flush cutting capability when needed

- 可选镇流器重量套件,以提高特定应用的生产力

- 轨道底盘提供牵引力,速度和机动性的平衡

- Reliable track undercarriage option leverages proven designs from Cat 307 and 308 mini excavators and an automatic tensioning system to ensure consistent performance and longer track life

- 能够在运行期间在转子转速之间进行电子切换

Highly Effective Material Removal

- High-capacity conveyors provide efficient removal of milled material with outstanding discharge control

- 宽阔的开口和无缝带有效地清除转子腔

- 调节皮带速度,以适应物料类型和生产速度

- The belt reverses for quick clean out, 而磁性乙烯基盖提供快速访问检查和清洁滚筒

Durable Cutting System

- The rotor drive system features a heavy-duty dry clutch, 双级皮带传动,自动张紧皮带,防止打滑

- Reinforced cutting chamber offers enhanced durability

- 硬化全长侧板滑雪板和防板鞋减少磨损和维护

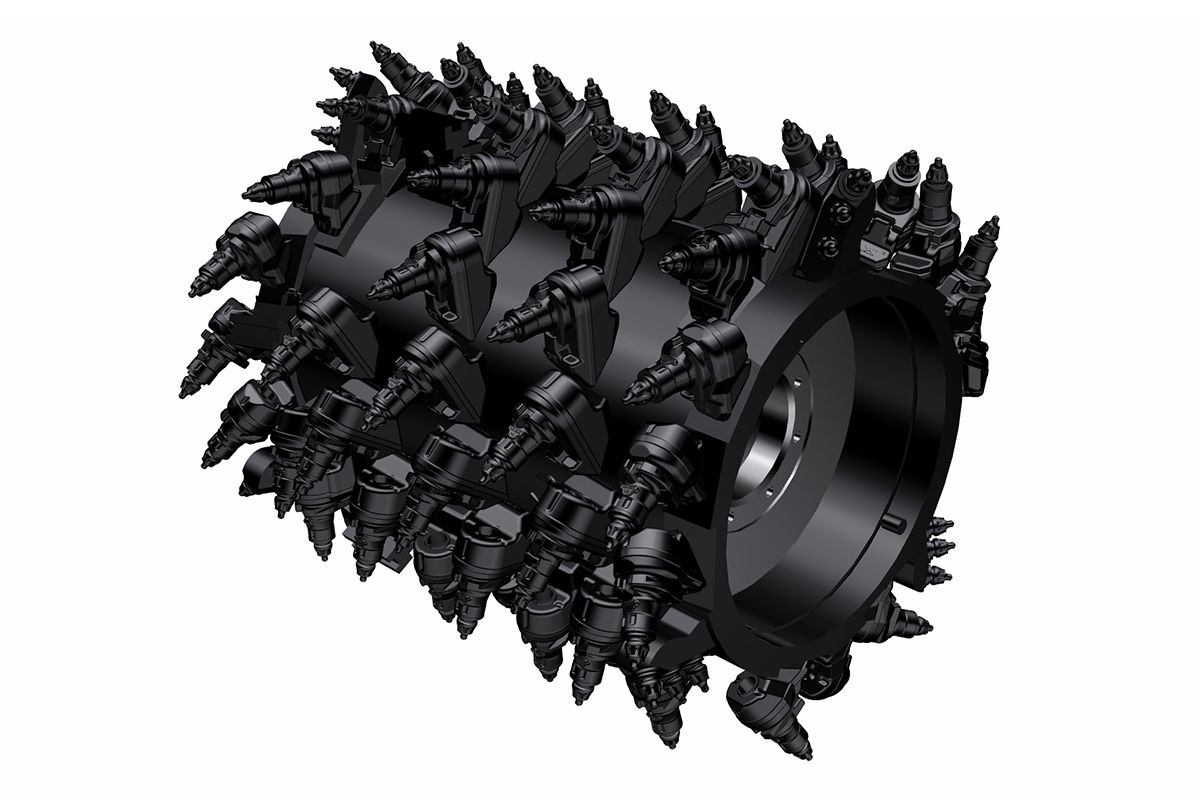

High Production System K Rotors

- Cat System K rotors feature efficient material flow with an excellent cutting pattern for numerous applications

- 锥形双保留设计确保刀柄在没有保留销的地方, bolt or setscrew, 加速更换和消除对紧固件或扭力的需要

- Toolholders, base blocks and kicker paddles are built from high strength alloy steel that’s abrasion resistant for extended life

- Optional diamond bits can extend replacement intervals up to 40 times longer than conventional carbide bits

Comfortable Work Environment

- Operate in comfort with a standard suspension seat, adjustable right arm console and intuitive, ergonomic controls

- A sliding operator station extends up to 215 mm (8.5 in) to provide improved visibility to the cutting edge

- Work day or night with backlit keypads and illuminate the work area around the machine with wide-dispersion LED or halogen lighting options

- Touchscreen displays provide access to gauge cluster, operating information, remote camera feeds, machine controls and diagnostics

- Optional remote cameras enhance visibility to the cutting edges, conveyor, and rear of the machine

- Cut closer to obstacles on either side using optional remote cameras with adjustable on-screen guidance lines

- An optional hydraulically powered canopy with extendible wing and handrail-mounted windscreen protect the operator from sun, wind, and rain

- Better direct exhaust up and away when milling close to buildings or ground personnel with the optional and stowable exhaust diverter

- 澳门新葡京博彩可选的除尘系统,最大限度地清除工作区域的灰尘

Integrated Cat Technology

- Achieve accurate, 可重复和自动切割精度与集成Cat坡度和坡度系统

- The optional grade control display can be positioned in the operator station or on the back of the machine to enable interaction with the grade system from the ground level

- 从任何机器显示器获得坡度和坡度的完全控制

- Easily adjust grade control values and sensors through the highly intuitive touchscreen interface

- 调整转子落入切口的速度,以获得最佳的机器控制

- 设置和自动转换到/退出剪切,并为未来的工作保存设置

- 澳门新葡京博彩障碍跳跃功能轻松清除切割路径中的障碍

- 增强全3D铣削操作(需要额外的硬件)

Simplfied Service, Low Maintenance Costs

- 澳门新葡京博彩大型维修门可以更容易地进入关键部件

- 免维护的轨道部件和易于更换的轨道垫降低了服务成本

- Standard ground-level controls and an optional hydraulically operated rotor turning device simplify bit removal and replacement

- 附件驱动系统允许在发动机关闭时澳门新葡京博彩选择机器功能

- Electrical system wiring is color-coded and numbered for easy identification and wrapped in a protective, abrasion-resistant nylon braid for longer life

- Monitor fluid conditions with regular sampling to help extend change intervals up to 500 hours engine oil, 6000 hours hydraulic oil and 12000 hours coolant

- Electronic Control Modules (ECMs) monitor machine systems to alert the operator of performance issues

- VisionLink® takes the guesswork out of managing your entire fleet–regardless of size or equipment manufacturer*–by providing maintenance needs, machine hours, location, fuel usage, idle time, diagnostic codes, 通过移动设备或桌面上的交互式仪表板,您可以获得更多信息, helping you make informed decisions that lower costs, simplify maintenance, and improve safety and security on your jobsite

- 远程Flash允许您在没有技术人员在场的情况下更新板载软件, allowing you to initiate software updates when convenient, increasing your overall operating efficiency**

- Remote Troubleshoot allows your Cat dealer to perform diagnostic testing on your connected machine remotely**

- Convenient parts availability, 经销商位置和服务维修套件简化了高磨损部件的订购

* Data field availability can vary by equipment manufacturer and is provided through an application programming interface (API).

** Must be within cell range coverage.

Sustainability

- The Cat C9.3B engine meets U.S. EPA Tier 4 Final, EU Stage V和Korea Stage V排放标准

- Cat U.S. EPA Tier 4 Final, EU Stage V, and Korea Stage V Final diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels* up to: 20% biodiesel FAME (fatty acid methyl ester) or 100% renewable diesel, HVO (hydrotreated vegetable oil) and GTL (gas-to-liquid) fuels. Please consult your Cat dealer or “Caterpillar Machine Fluids Recommendations” (SEBU6250) for details.

- Engine Idle Speed Management helps maximize fuel efficiency and reduce greenhouse gas emissions by elevating engine speed to an intermediate idle to complete specific tasks and returning to low idle when finished.

- Automatic Load Control helps you save fuel and reduces greenhouse gas emissions by automatically matching milling speed to engine load for maximum production at peak efficiency.

- Standby/Resume pauses major machine functions and lowers engine speed to conserve fuel and helps reduce greenhouse gas emissions during truck exchanges.

- 牵引力控制保持一致的牵引力,以提高机器效率, helps reduce fuel burn and greenhouse gas emissions.

- Cat Scheduled Oil Sampling (S•O•SSM) Services helps reveal excessive wear, 受污染的液体或其他“看不见的”问题可能缩短组件寿命. 在许多情况下,您可以通过澳门新葡京博彩流体监测延长油和冷却剂更换间隔. 有关更多信息,请咨询您的Cat经销商或机器的操作和维护手册.

- Cat Grade with Grade and Slope for cold planers allows for accurate material planning to help reduce overages during the paving process and increase final project quality for a longer lasting road surface.

- Don’t waste fuel idling. Cat VisionLink online fleet monitoring helps you manage idle time and reduce fuel burn and greenhouse gas emissions.

- VisionLink displays the CO2 emissions for monitored assets, 在选定的日期范围内,按燃料类型计算每天燃烧的运行时燃料.

* Tailpipe greenhouse gas emissions from lower-carbon intensity fuels are essentially the same as traditional fuels.